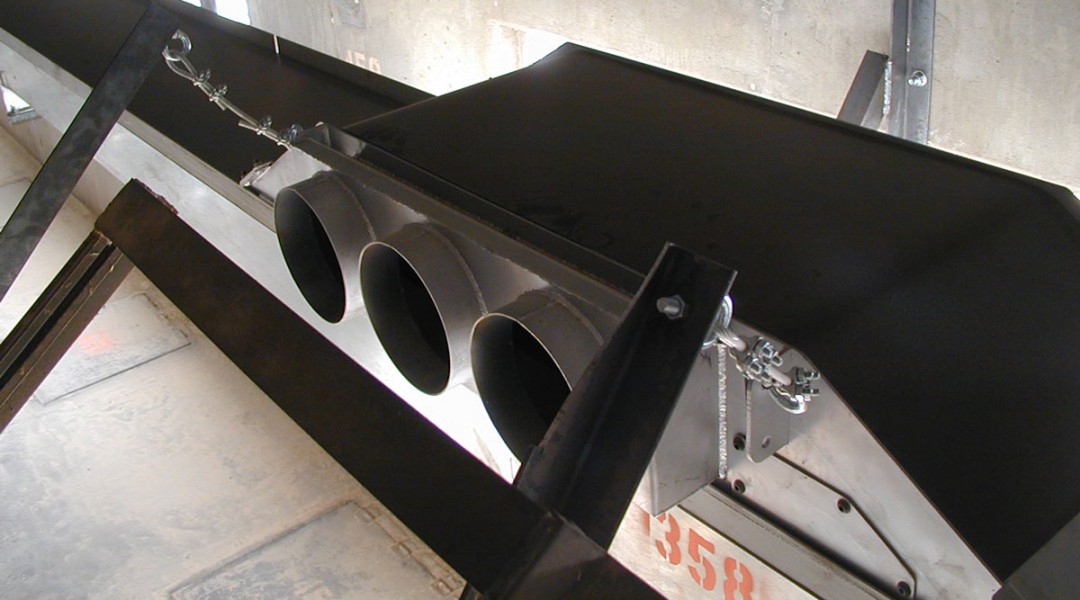

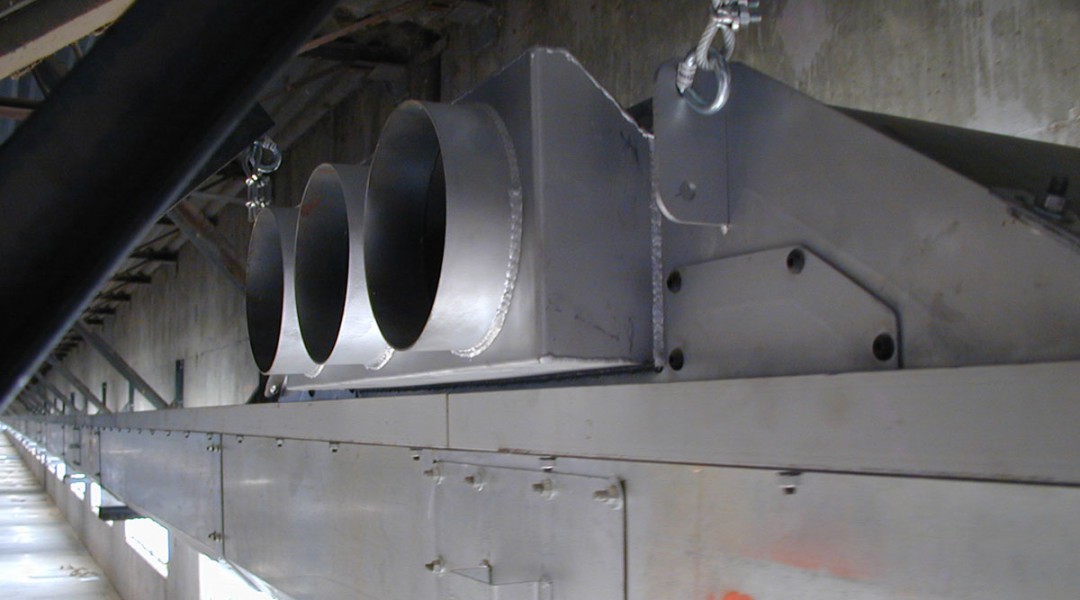

A zipper duct is made up using a stationary trough that is open on top. The open top is covered with a fabricated metal grate which is in turn covered with rubber belting. A sled travels the length of the trough on top of the metal grate. The rubber belting which lies on the grate is picked up by the sled and rides over the top of the sled as the sled moves on the trough.

Zipper Duct Operation

A vacuum is applied to the trough at a point along its length. This will be a round duct connection that is attached to the trough at either end or somewhere between the ends. Pipe is routed from the connection to the filter or separator that is handling the conveyed dust, smoke or fume. The vacuum is transferred to the moving sled. A round or rectangular connection is provided at the sled for a connection of pipe to the traveling source that is generating the dust, smoke or fume. A flexible connection, chain or cable is provided between the sled and the traveling source of the product. The traveling source pulls the sled back and forth on the trough.

Typical Applications:

- Gantry welders

- Plasma cutting tables

- CNC routing tables

- Head Houses at grain mills for the tripper belt

- Lathe operations that generate chips and dust

Zipper ducts have been successfully installed on equipment that travels in excess of 800 feet in distance and applications that require 16,000 CFM of air movement. Zipper ducts have also been installed on applications that move as little as 400 CFM over a distance of 10 feet